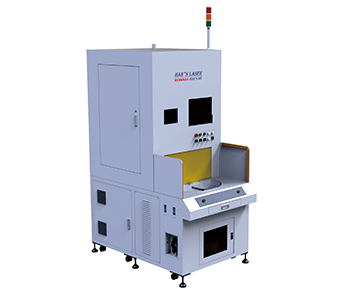

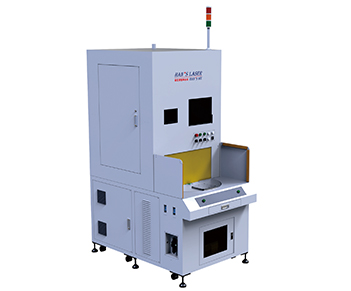

Rotary Double Station Laser Welding System

It consists of a laser, a chiller and a W-PCTSR322 workbench. The workbench adopts a rotating double-station design to improve production efficiency, and can realize four-axis linkage. It can complete point, straight line, circle, square or any plane graphics track welding composed of straight lines and arcs. It can be matched with a vision system to achieve precise positioning of the workpiece.

It is suitable for the spot welding and seam welding of various metal precision devices.

Control method: Industrial PC + motion control card

Drive mode: Servo drive

Motion platform: X, Y, Z three-axis electric platform; the X, Y, Z axis strokes are respectively 300mm, 200mm, 200mm; repeated positioning accuracy: ≤ ± 0.02mm, with a high-precision divider to achieve alternate work between two stations, repeated positioning accuracy: <±15 arc seconds.

Maximum load: 50kg.

Operation mode: manual loading and unloading, automatic welding.

Control system: Laser Welding System (completely self-independent intellectual property): powerful, stable, easy to operate, easy to learn and easy to maintain.

Workbench power demand: 220V/50Hz/2kW.

Dimensions of the worktable: 1000mm*1700mm*2300mm.

Guangdong Public Network Security No. 44030502000900

Guangdong Public Network Security No. 44030502000900