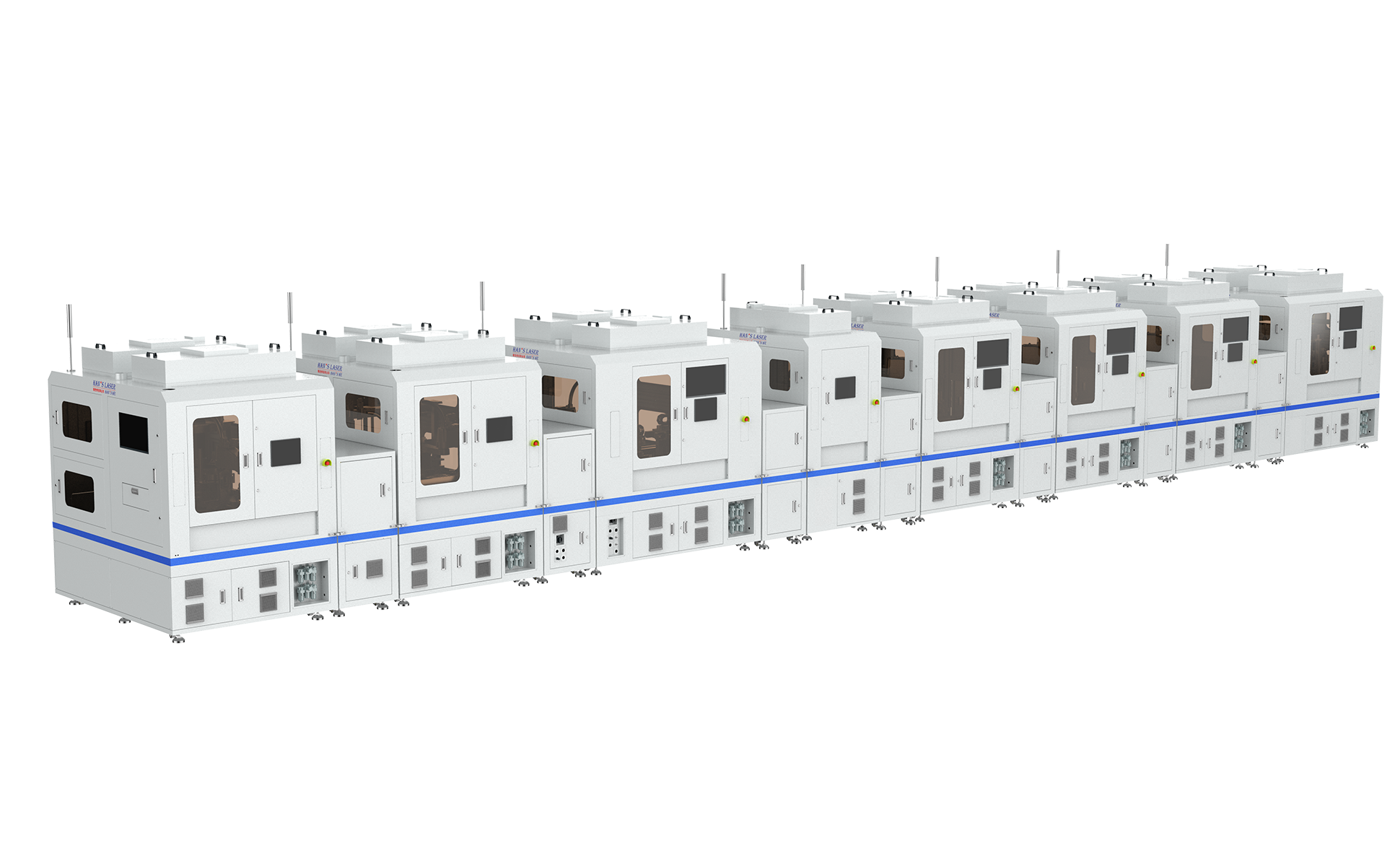

Product Introduction

This automatic welding station is suitable for automatic feeding, assembling, testing and welding of mobile phone middle plates and nuts, hooks, shielding covers, shrapnel and other precision small parts. Included modules: hook feeding, shielding cover feeding, nut feeding, shrapnel feeding, middle plate feeding, position detection, laser welding, material breaking module, post-welding detection, sorting processing, finished product unloading, fixture reflow, etc.

Product Features

1. The welding station integrates the functions of loading and unloading, assembling, testing and welding, and adopts a modular design;

2. Various feeding modes: Tray feeding, vibrating screen feeding and other feeding methods available;

3. Customized special automatic welding fixture, efficient and stable conveyor line body and high-precision positioning mechanism;

4. Integrated CCD positioning and laser height measurement to ensure product welding consistency and stability;

5. Use RFID, QR code and MES for information exchange, with quick maintenance function;

6. Adopt multi-PLC+PC joint control, stable operation, high efficiency, easy to debug and maintain.

Range of Applications

It is suitable for automatic assembly, welding and testing of mobile phone shells, middle frames, middle plates, studs, hooks, brackets, shrapnel and other mobile phone structural parts.

Guangdong Public Network Security No. 44030502000900

Guangdong Public Network Security No. 44030502000900